BACK TO Blog

BACK TO Blog

Asset Rental Management

Field Sales

Facilities Operations and Maintenance Strategies for Modern Facility Management

- May 02, 2025

- DreamzCMMS Team

- 8 minutes read

- May 02, 2025

- DreamzCMMS Team

- 8 minutes read

Why Facilities Operations and Maintenance Should Be Treated Like Strategy?

Facility upkeep used to be something you did not think about until something went wrong. But that model does not hold up anymore. Systems are more connected. Expectations are higher. And the cost of downtime or inefficiency is not something most companies can brush off.

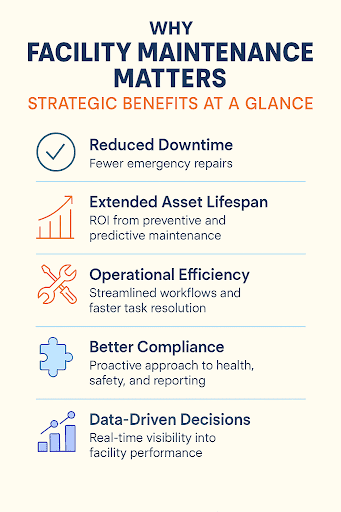

That is why facilities operations and maintenance are showing up in more strategic conversations. It is no longer just about fixing what breaks. It is about building resilience, reducing waste, and creating environments where people and assets perform better.

When facility operation and maintenance managers have the right tools and support, they do not just keep buildings running. They help drive the business forward. From energy savings and health and safety to compliance and customer trust it all connects back to how well your facilities operate. This is not just about maintenance anymore. It is about making sure your facilities are part of your growth plan.

The Cost of Staying Reactive

A lot of companies still rely on a “wait until it breaks” approach. On the surface, it seems cost-effective. No scheduled downtime. Fewer planned disruptions. But the truth is that it is a ticking clock that quietly chips away at margins, reputation, and safety.

When something fails unexpectedly, the response is almost always more expensive. Emergency parts, after-hours labor, and lost productivity add up fast. That is not even counting the impact on employee morale or customer experience when systems go offline.

Facilities operations and maintenance is not just about reacting faster it is about needing to react less often. That is the difference between running your facilities and letting them run you.

This is where the shift from reactive to proactive maintenance and predictive maintenance matters. Forward-thinking facility operation and maintenance managers are using real-time data and historical patterns to stay ahead of the problems. They are preventing emergencies before they happen and protecting budgets in the process.

If leadership sees facilities as a cost center, that mindset sticks. But when leaders recognize that smarter operations and maintenance in facility management drives performance, reliability, and savings, the value becomes hard to ignore.

The Strategic Role of Maintenance in Business Performance

Maintenance is often treated as background work. It is happening quietly, behind the scenes. But when it is not handled well, the consequences are anything but quiet.

For modern organizations, facilities management operations and maintenance impacts everything from service delivery and compliance to sustainability goals and workforce productivity. It is no longer just about keeping lights on or machines running. It is about driving performance from the ground up.

Smart maintenance does not just save money. It unlocks value. Buildings that operate efficiently cost less to run. Well-maintained assets last longer and require fewer replacements. Teams that are not stuck handling constant breakdowns can focus on high-impact projects that move the business forward. And then there is risk. Poorly maintained facilities open the door to health and safety issues, regulatory penalties, and public relations problems. That is not a line item. That’s a leadership concern.

C-suite executives are beginning to see what facility operation and maintenance managers have known all along: good maintenance is good business. When the right data, processes, and systems are in place, the results show up not just in buildings but on the balance sheet.

Want to make facility maintenance part of your growth strategy not just a line item?Discover how DreamzCMMS facility management software helps organizations turn facilities operations into a competitive advantage. From predictive tools to asset tracking and real-time visibility, it is built for leaders who expect more from their infrastructure. |

What Strong Maintenance Looks Like in Practice

In most companies, maintenance is not broken, it is just fragmented. A few things are working, others are behind, and the rest is reactive. But when you bring the right parts together, something shifts. Maintenance stops being a support function and starts becoming part of performance.

Here is what tends to make the difference:

1. You Get Ahead of Problems

If you wait for systems to fail, you will always be reacting. The shift to proactive maintenance and predictive maintenance is not about buzzwords, it is about not getting caught off guard. Teams that can spot trouble early spend less time scrambling and more time planning.

2. Assets Are Tracked and Prioritized

Not all equipment is created equal. When you have a clear view of your critical infrastructure thanks to smart asset management you stop guessing. You know what matters most, what needs attention, and what can wait.

3. Tasks Do not Get Lost

It is easy to miss things when processes vary from site to site. Standardizing facility maintenance tasks creates rhythm. It keeps the team aligned, no matter who is on shift or which location they are in.

4. Leadership Pays Attention

The best outcomes happen when facility operation and maintenance managers are not fighting for buy-in. When leadership sees this work as strategic not just necessary it creates alignment. Budget conversations change. So does accountability.

5. You Can See What is Happening Now

Delayed reporting does not cut it anymore. Executives want to know what is going on across sites in real time. That is where modern tools and mobile dashboards come in. They make operations and maintenance in facility management visible and measurable. None of this is about perfection. It is about building a system that holds up when things get busy and one that helps you grow without breaking what is already working.

Executive Insights

Measuring the ROI of Maintenance Investments

How much faster can your team complete routine work when maintenance tasks are standardized and tracked? How many fewer hours are spent responding to breakdowns when you shift toward predictive maintenance?

Then there is the cost. Facilities operations and maintenance done well does not just avoid emergency repairs it reduces long-term wear and extends the life of critical assets. That is real savings, especially across multiple locations.

Uptime is another metric that matters. When systems run without interruption, business continues without disruption. For many sectors, every hour saved translates directly to revenue protection. There is also compliance and health and safety. Failures in these areas do not just cost money, they put people at risk and damage your brand. The right tools and processes reduce exposure. They help teams stay ahead of risk and maintain control.

And perhaps most important for leadership: confidence. With real-time visibility and reporting, decision-makers can act on facts, not assumptions. That level of control and foresight is hard to put a dollar value on but it changes how an entire organization moves.

When facilities management operations and maintenance is viewed as an investment instead of an expense, the return shows up across the board.

Companies using predictive maintenance report a 25–30% reduction in unplanned downtime and a 15% increase in asset lifespan.

— Source: Industry Facilities Benchmark, 2024

Executive Takeaway

Maintenance is not just about repairs. It is about keeping the whole operation balanced.The more facilities grow, the more moving parts there are and the harder it gets to stay ahead without a plan. That is why facilities operations and maintenance needs to be more than reactive. It should be part of the way the business moves.When the systems run right, people notice less. But when they fail, everyone notices.

Leadership is not about waiting for problems to show up. It is about building the kind of structure that does not let those problems sneak in. That is what solid operations and maintenance in facility management can do quietly, reliably, in the background.

You do not need a massive transformation to get started. A few small changes by adding predictive maintenance, organizing core maintenance tasks, tightening up asset management can make a big difference fast. It is not about perfection. It is about control, stability and being able to grow without leaving your facilities behind. That is what makes maintenance strategic. And that is why it deserves a seat at the table.

Ready to align your facility maintenance strategy with business performance?Discover how DreamzCMMS supports facility operation and maintenance managers with the tools and insights needed to scale smarter, operate safer, and lead with confidence. Book a free consultation to explore how our platform aligns with your goals. |

Ready for More?

Talk to one of our CMMS experts and see how DreamzCMMS can simplify your maintenance operations.

Book a free consultation